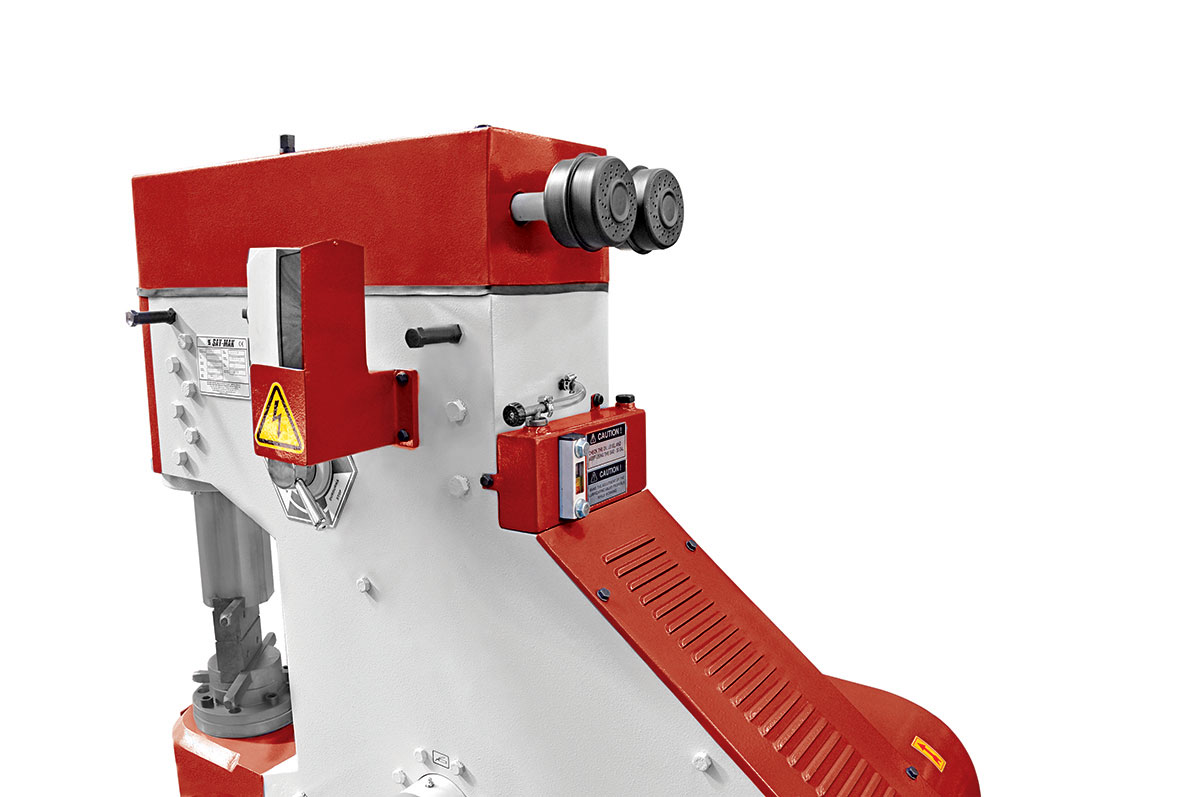

PNEUMATIC FORGING HAMMERS

These machines named forging hammers, power hammers or pile drivers works by two cylinders, one at the back and another one at the front which is the one that impulses the stem for the stroke. The motor for the power hammer moves the rod of the back cylinder or compressor and the compressed air goes to the front cylinder through the valves that control the stroke displacement. No need for any external compressor. They are manufactured in welded and mechanized steel sheet. They are used in many blacksmith workshops to make all kinds of forging ornamental pieces which eases the job of moulding hot steel. Different tooling are used: for inlaying, moulding, cutting, piercing, rivetting, embossing, etc, in all kinds of metals.